Food powders & Encapsulation

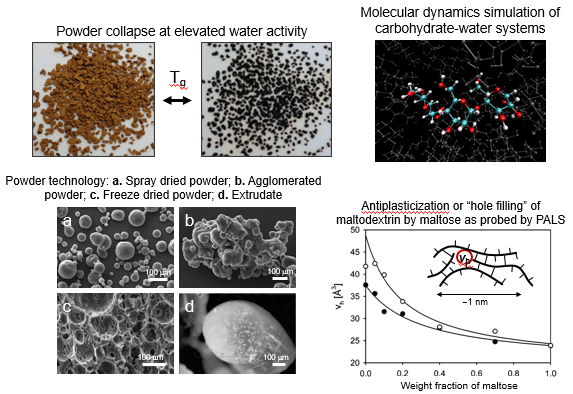

Carbohydrates in the glassy state are excellent oxygen barriers and are widely used as encapsulation matrices for oxidation sensitive food ingredients and pharmaceutics. Their barrier properties are optimized by antiplasticization of the carbohydrate matrix by low molecular weight diluents such as mono- or disaccharides or polyols. This mechanism is often colloquially known as “hole filling”.

Based on years of extensive investigation of the molecular packing of amorphous carbohydrates in the glassy state using Positron Annihilation Lifetime Spectroscopy (PALS), we are able to closely predict which type of matrix composition is needed for optimal performance for a specific application. In this, we also perform an investigation of the sensitive of the powder to water, and the impact on the glass transition temperature.

We employ the state diagram concept to control the physical state of powders drying processing. We usually focus here on spay drying, agglomeration and freeze drying, taking into account powder properties such as density, flowability and dissolution characteristics.